About Pag Sheetmetal in London

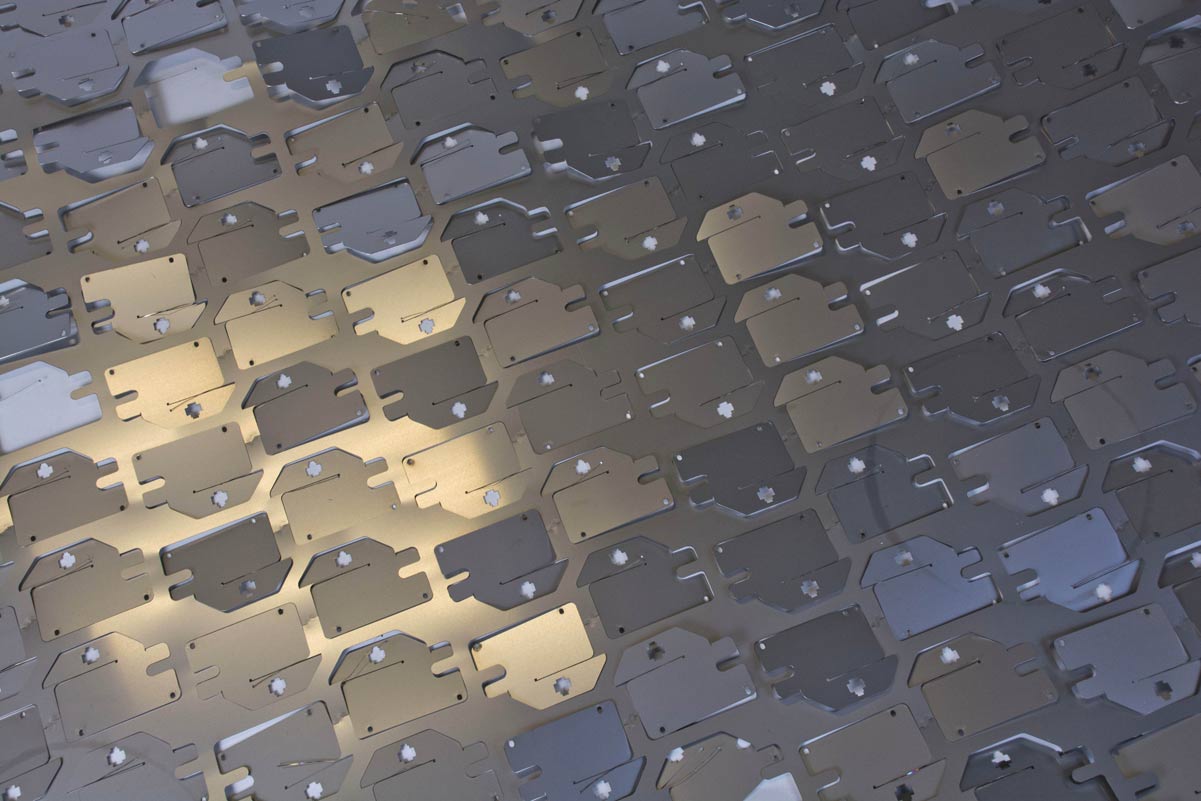

PAG Sheet metal has the facility to manufacture single units, to multi batch specifications in fine tolerance sheet metal work using a range of metals including mild steel, stainless steel, brass, copper, aluminium alloys and titanium.

-

Continual investment in the latest technology

-

Latest technology keeping us ahead of the game

-

Products made to each any every customers specification!

PAG are accreditated

At PAG we in machine technology

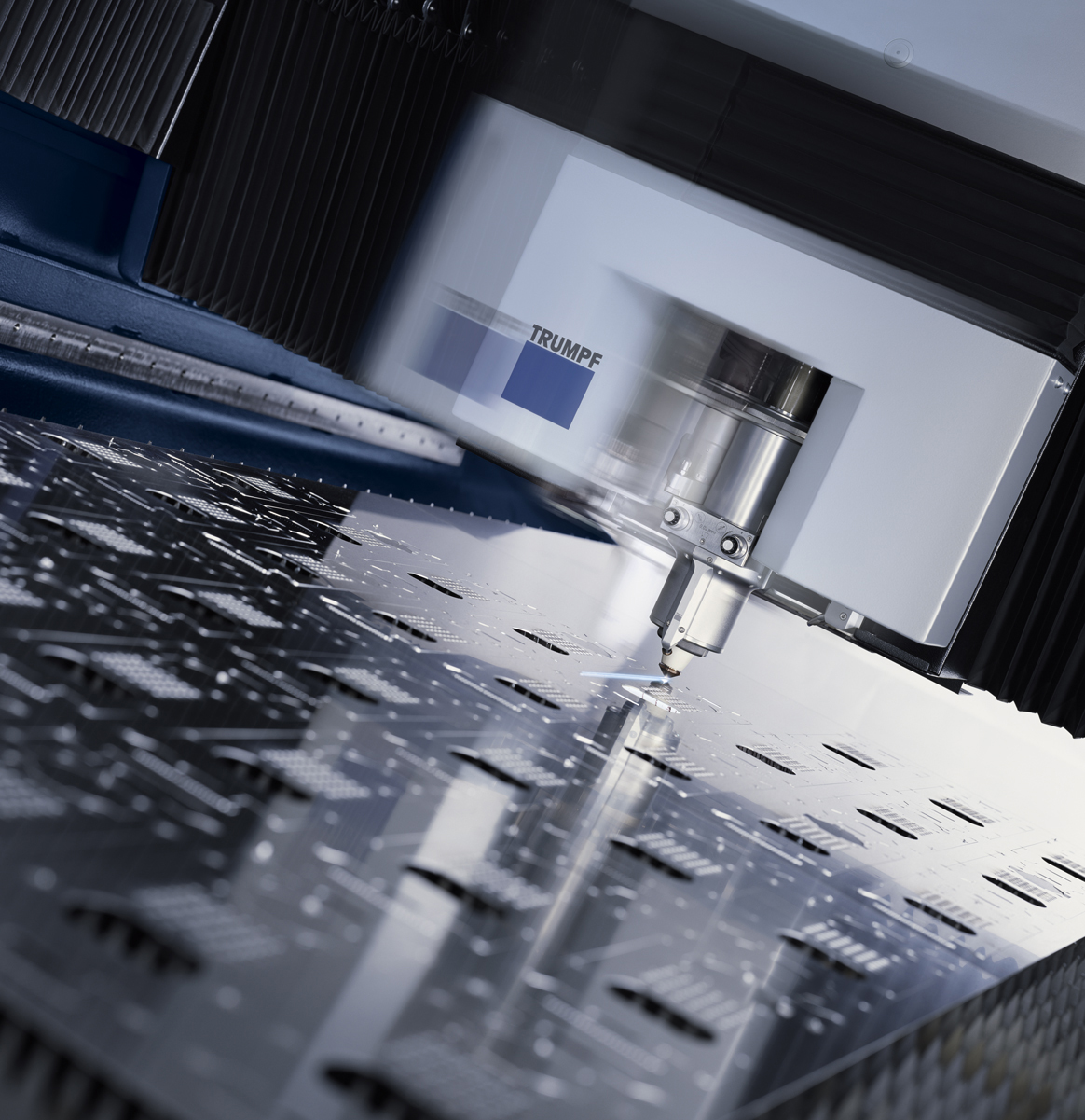

PAG have invested considerably into new machine technology to run alongside the already highly impressive equipment including a Trumpf 3030 fiber laser cutting machine and a CNC punching machine to make PAG sheet metal a highly competitive sheet metal company of its kind.

- Building customer loyalty

- Our customers demand high quality products

We have built up a strong reputation

The company has built up a good reputation, which has been spread by word of mouth. PAG Sheetmetal always attempts to keep to the agreed delivery times and regards the level of customer service as one of its main priorities along with the quality of the products. Because of this PAG Sheetmetal has a large customer data base.

Our success is down to our loyal workforce

PAG Sheet metal's loyal workforce also helps explain the company's success to date. The Sheet metal workers are time served tradesmen, which guarantees the quality of the products produced.

- Our customers demand highquality products

- Free delivery and collection service available

Our company downloads

LASER CUTTING - PRESS BRAKE - WELDING - MIG-TIG-ARC - ROLLING - TURNING - FORMING - GRINDING - CUTTING - POWDER COATING - FABRICATION - FINISHING - ASSEMBLY & PACKING - IPG HAND HELD LASER WELDING